Dora Makine Conveyor Systems Manufacturing

With over 15 years of experience in the industrial field, Dora Makine manufactures high-quality conveyor systems tailored to the needs of each sector. To make our customers’ production processes more efficient, safe, and cost-effective, we provide customized solutions for every requirement and demand.

At Dora Makine, with our expert production teams and experienced technical staff, we are at your service for all kinds of conveyor system design and manufacturing. Share your needs with us, and with our technical support, we will offer customized solutions and manufacture your system in compliance with the highest quality standards.

- Heavy-Duty Conveyors: Systems designed for the safe and efficient transport of heavy loads in industrial applications. Strong and durable with high load capacity.

- Aluminum Frame Conveyors: Lightweight and durable, aluminum frame conveyors provide ideal solutions for various industries.

- PVC Belt Conveyors: Suitable for light to medium loads, PVC belt conveyors are flexible and can be easily integrated into different production lines.

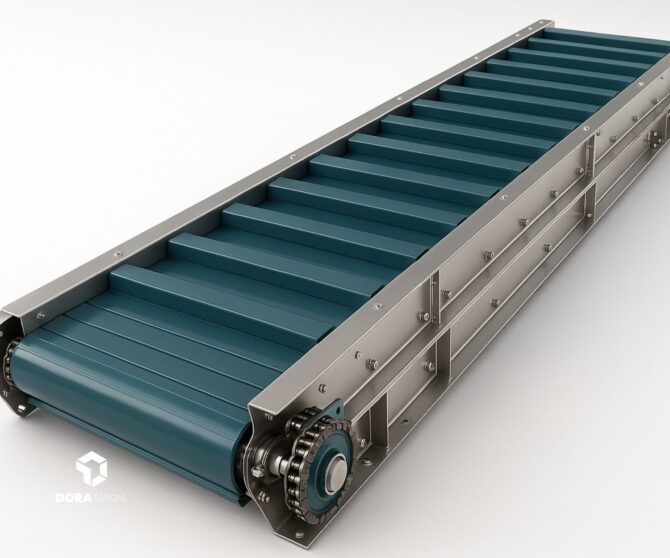

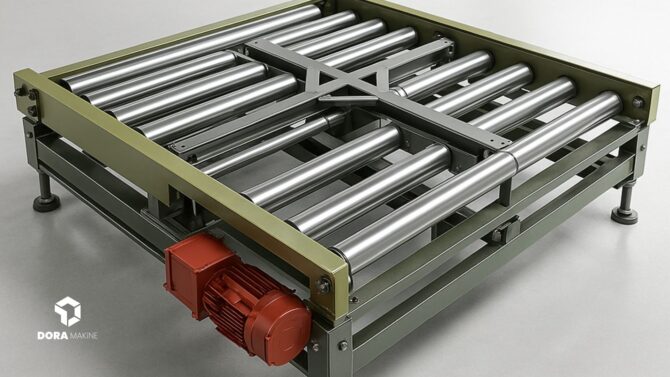

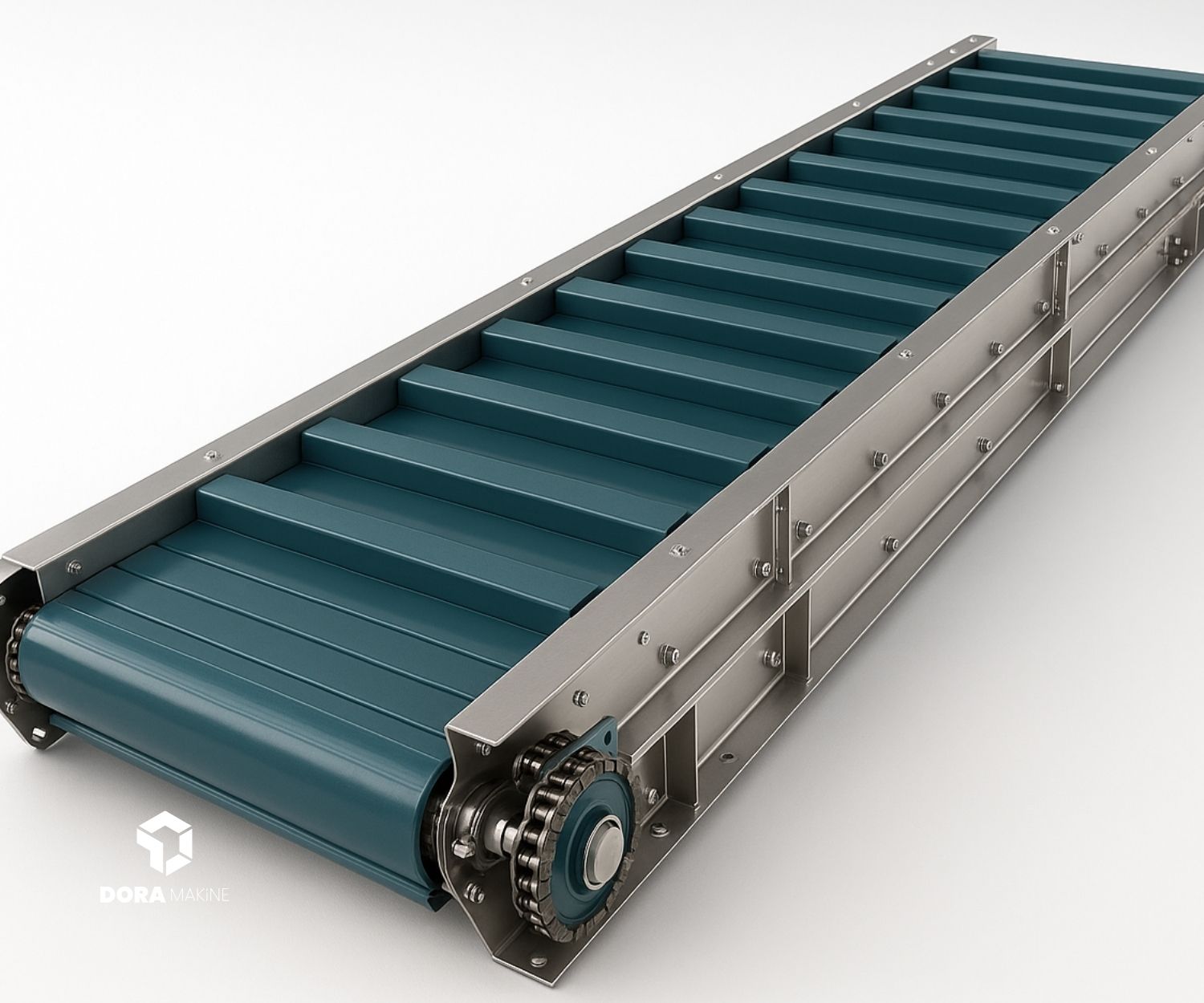

- Roller Conveyors: Durable and long-lasting conveyors that enable high-speed transport, offering efficient handling solutions.

- Detector Conveyors: Used to detect metals and foreign objects on products, ensuring safe production processes.

- Modular Belt Conveyors: Provide fast installation and high flexibility, easily integrating into any production line.

- Accordion Conveyors: Highly flexible and with strong load capacity, accordion conveyors are ideal solutions for areas with space limitations.

- Elevator Conveyors: Suitable for vertical transport needs, elevator conveyors ensure materials are moved with high efficiency.

- Telescopic Conveyors: Adjustable in length, telescopic conveyors save time, particularly in shipping and loading operations.

At Dora Makine, we aim not only to deliver products but also to provide integrated systems that ensure operational efficiency, cost-effective solutions, and time savings. We stand by our customers with quality production, engineering support, and technical service at every stage.

- Customized Solutions: We analyze customer needs thoroughly and design tailor-made conveyor systems accordingly.

- High Quality: All our products are manufactured according to international quality standards and undergo rigorous testing.

- Increased Efficiency: Our conveyor systems speed up your production processes, reduce labor costs, and boost productivity on your line.

- Advanced Technology: Dora Makine follows the latest technological developments to provide innovative solutions tailored to industry demands.

- Reliability and Durability: Our conveyor systems are long-lasting, user-friendly, and require minimal maintenance, providing a key advantage for operational continuity.

Conveyor Systems That Enhance Industrial Efficiency

In industrial production processes, efficiency is a critical factor that directly impacts the success of businesses. Conveyor systems are one of the most essential components of these processes. With evolving technologies and growing demands, conveyors not only serve as transport mechanisms but have also become vital tools that increase productivity, save time, and reduce costs.

The contribution of conveyor systems to efficiency is evident in faster material handling, optimized labor use, and the prevention of production errors. For instance, manual handling in a production line can cause both time loss and higher labor costs. Conveyor systems significantly reduce labor needs in this area and increase production speed. However, not every system is suitable for every process. So, which conveyor system type provides the best efficiency for which industrial needs?

When selecting conveyor systems to improve industrial efficiency, factors such as load capacity, speed, durability, and modularity should be considered. The right choice directly impacts overall business efficiency and offers significant long-term gains. For example, conveyor systems used in the automotive industry enable the safe and fast transport of heavy parts, while in the food industry, systems designed with hygiene and speed in mind are preferred.

Conveyor System Solutions for Diverse Needs

Conveyor systems can be designed and implemented according to the specific needs of each industry. That’s why evaluating your company’s requirements is crucial when selecting conveyor solutions. Different industries require different systems depending on their material handling demands. So, which conveyor type works best for which sector?

For instance, since hygiene is critical in the food industry, stainless steel and hygienic design conveyors are favored, whereas in the automotive sector, load capacity and durability are key. In electronics manufacturing, where delicate handling is required, conveyors designed to minimize vibrations are used. Conveyor solutions include pallet conveyors, belt conveyors, chain conveyors, and modular conveyor systems, each tailored to specific applications.

Each sector can be provided with tailored solutions. A chain conveyor with high load capacity is ideal for transporting large, heavy items, while belt conveyors are more suitable for small and lightweight materials. Moreover, modular conveyor systems offer flexibility, allowing easy integration into different production lines and smooth adaptation to various processes.

Durable Conveyor Systems for Heavy Load Transport

Heavy load handling is particularly important in large-scale industries such as automotive and heavy manufacturing. The sheer weight of transported items requires conveyor systems with extra durability. What are the key features of heavy-duty conveyor systems?

These conveyors must provide high load capacity while ensuring long-term reliability. Conveyor belts should be made of high-strength materials, and all system components should be resistant to wear and tear. Regular maintenance and inspection are also vital to ensure smooth operation when handling heavy loads.

For example, chain conveyors used in the automotive sector for engine parts provide both durability and consistent, safe transport. In addition, the speed of these systems must be optimized. Excessive speed may compromise safety, so balancing transport speed with reliability is essential.

Modular Conveyor Systems Designed with Advanced Technology

Advancing technology has significantly improved the design and functionality of conveyor systems. Modular conveyors are among the best examples of these advancements. With their flexible structure and ease of installation, modular systems adapt quickly to different production lines and requirements, delivering innovative solutions that enhance efficiency at every stage of production.

One of the greatest advantages of modular conveyors is their adaptability during use. Components can be easily replaced or maintained, ensuring long-term efficiency. Moreover, modular systems can be scaled up or down according to capacity needs. With advanced technology, these systems can be digitally monitored and adjusted for performance optimization.

Digital technologies also bring automation and analytics into conveyor systems. Sensors and monitoring systems allow real-time observation, enabling early fault detection and quick response. Additionally, data analytics improve efficiency and provide valuable insights into production processes.

Fast and Efficient Material Handling: The Advantages of Conveyor Systems

Conveyor systems are indispensable for achieving speed and efficiency in production processes. Time lost during material handling directly affects productivity. By enabling faster and more efficient transportation, conveyors shorten production cycles and allow businesses to increase output. What are the main advantages of conveyor systems?

First, conveyors automate material transport, significantly reducing the need for manual labor. This not only cuts labor costs but also enhances workplace safety. Furthermore, automation minimizes human errors, improving product quality. High-speed conveyors ensure uninterrupted workflows, keeping production lines running smoothly.

For instance, in an automotive assembly line, conveyors quickly transport the required materials to workstations. Workers can then focus entirely on their assigned tasks, accelerating the production process. This results in substantial time savings for the business. Additionally, proper handling during transport prevents material damage, improving overall product quality.