Dora Makine Screw Conveyor Manufacturing

At Dora Makine, with over 15 years of industry experience, we provide our customers with high-quality, durable, and reliable solutions for all types of screw conveyor manufacturing. With our engineering expertise and advanced production technologies, we design and manufacture screw conveyors tailored to meet all your industrial needs.

Dora Makine offers a wide range of solutions in screw conveyor manufacturing with the following features:

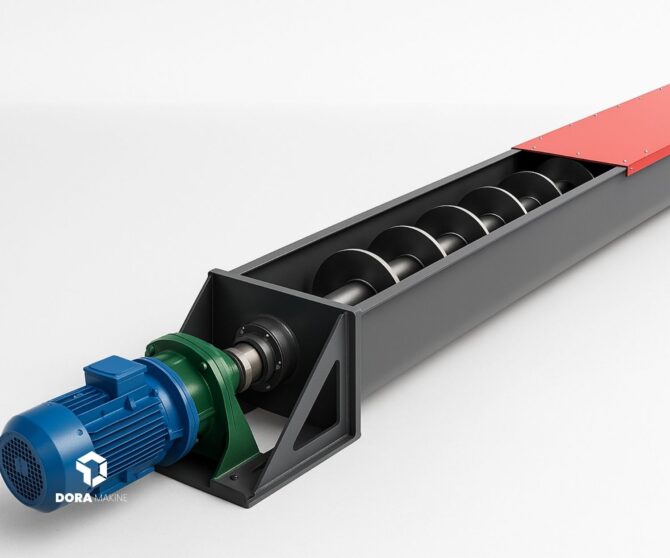

- Standard Screw Conveyors: Durable and efficient screw conveyors designed for industrial use.

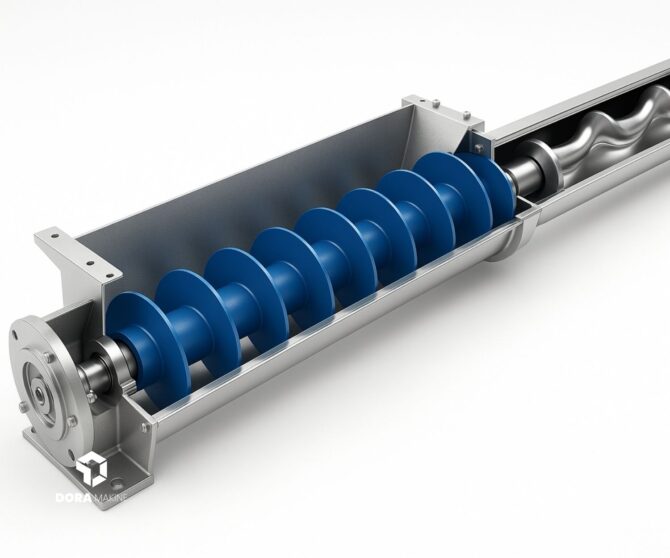

- Custom-Designed Screw Conveyors: Specially developed screw conveyors designed to meet specific application requirements based on customer demands.

- High-Performance Screw Conveyors: Screw conveyor solutions that provide superior performance and withstand heavy-duty and challenging working conditions.

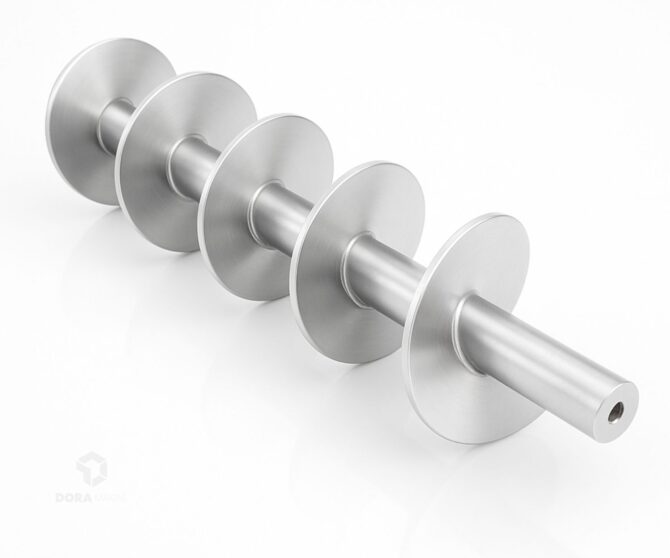

- Stainless Steel Screw Conveyors: Manufactured from stainless steel material for use in corrosive environments.

Each of our products undergoes a meticulous quality control process and is manufactured in compliance with the highest industry standards.

Why Dora Makine Screw Conveyors?

- Excellent Quality: We always prioritize quality in our production processes, manufacturing the most durable and long-lasting screw conveyors.

- Advanced Technology: With modern production technologies and CNC machines, we can carry out every type of screw conveyor manufacturing with precision.

- Flexibility and Customization: We provide tailored solutions to meet your needs, successfully completing all kinds of special projects.

- On-Time Delivery: By focusing on customer satisfaction, we ensure your projects are delivered on time.

- Competitive Prices: We offer high quality at competitive prices within the industry.

Expertise and Experience in Screw Conveyor Manufacturing

Our team of engineers, each an expert in their field, provides the most suitable solutions for all your screw conveyor needs. Through quality control and testing at every production stage, we aim for excellence at every step. With its commitment to excellence in screw conveyor manufacturing, Dora Makine continues to be a trusted business partner in the industry.

Advantages of Working with Dora Makine

- Customized Designs: We offer designs that meet the specific needs of your business.

- High Quality and Performance: We provide durable and long-lasting screw conveyors to ensure the efficient operation of your industrial machinery.

- Customer-Centered Approach: We work with you at every stage of your projects to help achieve exactly the results you want.

- Continuous Improvement: By keeping up with technological advancements, we continuously improve our production processes.

At Dora Makine, with the high quality and customized solutions we provide in screw conveyor manufacturing, we deliver the most suitable and efficient solutions for your industrial needs. By working with us, you can take quality and reliability in your projects one step further.

What is a Screw Conveyor?

A screw conveyor is a mechanical component, usually in a helical shape, used in various industrial applications. Operating by rotating around a shaft or axis, screw conveyors are effectively used to transport liquids, gases, or solid materials. These helical structures can also perform various functions in mechanical systems, such as power transmission, rotary motion, and material handling. So, what distinguishes screw conveyors from other mechanical components, and why are they so widely used?

Screw conveyors are particularly flexible in design. These helical structures are often used in conveying lines, mixing machines, screw mechanisms, and even some drive systems. The materials and structure used in the design directly affect the durability and functionality of the screw. With the right design and material selection, screw conveyors can operate efficiently and have a long service life.

Screw conveyors can generally be classified into three main categories: conveying screws, drive screws, and mixing screws. Conveying screws are used to move materials from one point to another, drive screws provide mechanical energy transmission, and mixing screws are designed for blending liquids or solids evenly. Each type of screw conveyor is designed and used for a specific application.

Screw conveyors are widely used across different industries. For example, in the food processing industry, screw conveyors are used for mixing processes, while in the automotive sector, they can be used for power transmission. They also play important roles in agricultural machinery, conveying systems, and even in some areas of the chemical industry. Thanks to their high efficiency and low energy consumption, screw conveyors are preferred in many industrial fields.

In conclusion, screw conveyors are an important part of mechanical design and versatile components capable of performing critical tasks in industrial applications, such as material handling, power transmission, and mixing. Each screw conveyor type is designed to serve a specific purpose, and with the right design and material selection, they can work with great efficiency.

Screw Conveyor Design and Material Selection

Screw conveyors play a critical role in industrial machines and systems. These mechanical components are typically used for processes such as transporting liquids and solids. The success of screw conveyor design largely depends on material selection. So, what is the importance of material selection in screw conveyor design? A good design with the right material choice not only improves system efficiency but also ensures long-lasting and reliable performance.

Material selection in screw conveyor design must first be based on application requirements. The ideal material should be determined considering both mechanical properties and environmental factors. For instance, stainless steel is preferred for screw conveyors in applications that require high strength and corrosion resistance. On the other hand, special alloys or coatings may be used for high-temperature or abrasive environments.

Another important factor in screw conveyor design is the machinability of the material. For screws that will operate under harsh conditions, machinability, durability, and elasticity need to be well-balanced in material selection. Choosing the right material is a key element that directly impacts screw conveyor efficiency.

Screw Conveyor Manufacturing Methods

Screw conveyor manufacturing depends not only on the right material choice but also significantly on the production methods. A good production method ensures screw conveyors perform well, last long, and optimize costs. So, which methods deliver the best results in screw conveyor manufacturing?

Screw conveyors are usually produced using three main methods: casting, forming, and welding. Casting is particularly suitable for large-scale and complex designs. Forming is commonly used to shape the screw into the desired form. Welding, on the other hand, produces screw conveyors by joining metals under high heat. Each method has its pros and cons. For example, casting can be more costly, while forming is faster and more efficient.

A good production method increases the reliability of the screw and minimizes time loss during production. Additionally, compatibility between design and material should also be considered. To maximize quality in screw conveyor manufacturing, choosing the appropriate production method is the first step toward success.

Types of Screw Conveyors and Application Areas

Screw conveyor types vary depending on their purpose and working conditions. Each type offers tailored solutions for specific applications. So, which screw conveyor type is best suited for which application area?

Generally, screw conveyors are produced in three main types: open screw conveyors, closed screw conveyors, and hybrid screw conveyors. Open screws are commonly used for transporting materials and often provide cost-effective solutions. Closed screws are preferred for special conditions, such as transporting liquids and gases. Hybrid screws combine the advantages of both types and are used in more complex systems.

The choice of screw conveyor type is determined by the requirements of the application area. For example, in the food industry, where hygienic conditions are a priority, closed screws are preferred, while in construction, more durable and robust designs are favored. Factors such as environmental conditions, the properties of the material being conveyed, and the conveying distance should also be considered in type selection.

Quality Control in Screw Conveyor Manufacturing

Screw conveyor manufacturing is a process where quality must be continuously monitored. Quality control ensures not only the production process but also the reliability of the final product. So, how can quality be guaranteed in screw conveyor manufacturing?

Quality control in screw conveyor manufacturing involves several stages. From material selection before production to tests conducted during production, every step must be closely monitored. Material tests include factors such as metal strength and elasticity. During production, screws should be tested for size, shape, and surface quality. In addition, performance tests carried out before final assembly are also a part of the quality control process.

The importance of quality control lies in ensuring screw conveyors operate both safely and efficiently. Errors made during production can result in costly repairs if detected later. Therefore, implementing quality control at every stage guarantees long-term success.

Screw Conveyor Performance and Efficiency Evaluation

Screw conveyor performance and efficiency are critically important, especially in industrial applications. A good screw conveyor not only handles transportation efficiently but also improves the overall efficiency of the system. So, how can screw conveyor performance be evaluated?

Performance depends on various factors, from conveying capacity to speed. Efficiency can be measured by considering energy consumption during transport, blockages, and friction in the system. Additionally, the type and amount of material conveyed are important factors affecting performance. Even small changes in screw design can significantly impact energy consumption.

When evaluating performance, potential improvements that increase efficiency should also be considered. These improvements, combined with material selection, design, and production methods, can significantly enhance overall system efficiency. Furthermore, regular maintenance and inspections are essential factors in boosting performance and extending the lifespan of screw conveyors.

In conclusion, screw conveyor design and manufacturing are technical processes that must be handled carefully. Every stage has a significant impact on performance, efficiency, and quality. With good design, correct material selection, and effective production methods, screw conveyors secure an important place in industrial systems and contribute to success.