In today’s industrial production processes, efficiency and customized solutions are key determinants of competitiveness. In this context, the production of vibrating screens is undergoing a major transformation in technology and engineering. New technologies not only increase production speed but also make it possible to provide more customized solutions. So, how do these innovative technologies make a difference?

The use of vibrating screens in material separation, solid-liquid separation, and many other industrial processes is becoming increasingly widespread. The fact that these machines are becoming more efficient with advancing technologies not only helps reduce costs but also paves the way for environmentally friendly production processes. For example, energy-efficient motors and systems operating at low noise levels contribute to workforce health.

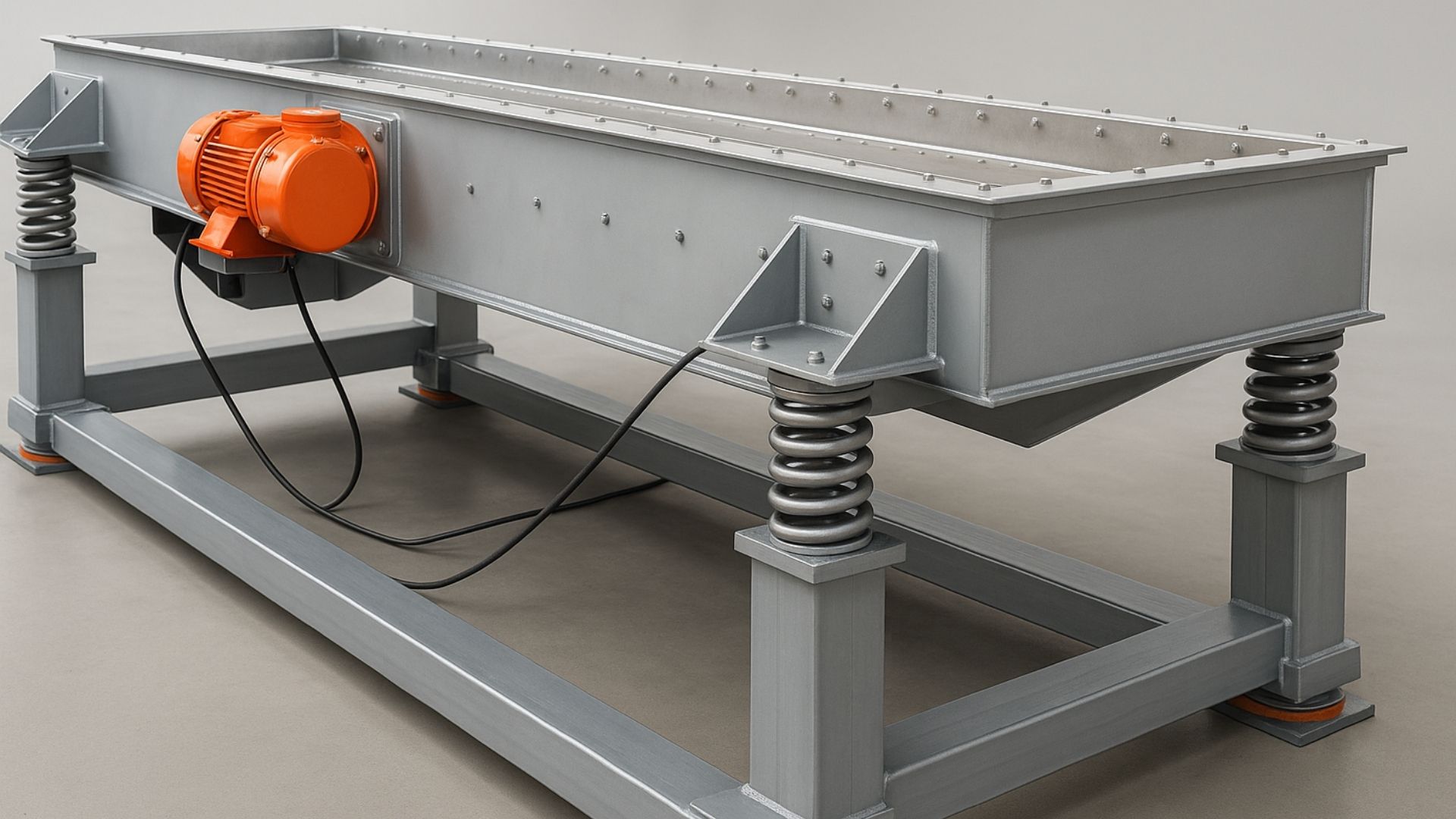

Next-generation vibrating screens feature more sophisticated vibration systems to increase their speed and efficiency. These machines optimize vibration intensity and direction with smart sensors, enhancing the effectiveness of the separation process. It can be said that such innovations provide an important foundation for creating designs tailored to customer needs. In addition, thanks to automation, operator errors are minimized and the maintenance processes of machines become more predictable.

Advanced Engineering in Vibrating Screen Design: Customizations That Enhance Performance

Advanced engineering applications in vibrating screen design play an important role in optimizing production processes. Since the requirements of industrial processes are constantly changing, designs need to be flexible and modular. Advanced engineering improves both the functionality and durability of machines, enhancing user experience and production quality.

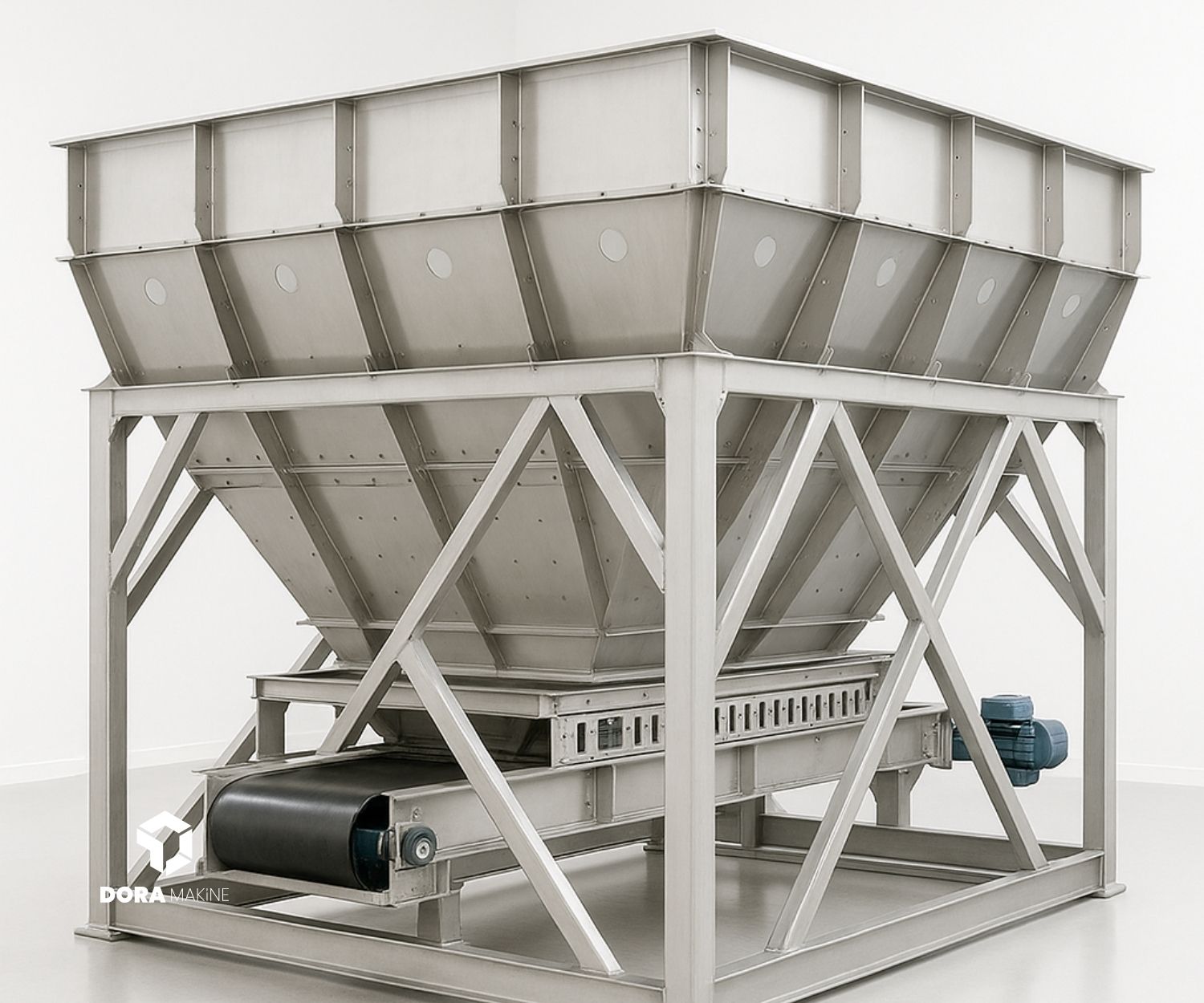

In many industries, there is a need for material separation in different sizes. Therefore, customizable platforms and interchangeable elements in vibrating screen design provide a significant advantage. For example, screens of different sizes can be quickly replaced in machines designed for specific operations. This increases the operational flexibility of manufacturers.

Advanced engineering is not limited to machine design alone. The durability of the materials used, the efficiency of vibration systems, and even the environmental impact of the machine must also be considered. For example, designs that optimize airflow reduce energy consumption while increasing efficiency. Making vibrating screens more durable reduces maintenance costs and allows manufacturers to achieve long-term gains.

High-Efficiency Vibrating Screen Systems: Innovative Solutions Shaping the Industry

The transformation of vibrating screens into high-efficiency systems is one of the significant developments in the industry. Especially in large-scale production facilities, the efficient operation of machines reduces costs and minimizes downtime in the production process. Efficiency is not only about the capacity of the machines; it is also related to how much energy they consume, how long they operate, and how often maintenance is required.

Improvements made in machine design are highly important for vibrating screens to operate with high efficiency. For example, improved motors provide more performance while consuming less energy. In addition, quieter operation of machines also paves the way for environmentally friendly production processes. Such improvements make a significant difference, especially in energy-intensive industries such as food processing, mining, and chemicals.

A high-efficiency vibrating screen system is also less prone to malfunctions. The use of high-quality materials and meticulous engineering designs increase the durability of machines. This minimizes maintenance and repair needs, saving users both time and cost. So, how do these high-efficiency systems affect competition in the industry? Innovative solutions enable manufacturers to produce faster and more cost-effectively, giving them a market advantage.

Modern Approaches Increasing Quality and Efficiency in Vibrating Screen Production

Vibrating screen production is undergoing a significant transformation thanks to modern approaches that aim to increase quality and efficiency. Improving quality in industrial production processes is a factor that directly affects both product quality and the effectiveness of the production process. However, balancing efficiency with quality is not always easy.

Modern production methods help optimize quality control systems and processes. Every component used in the production process is carefully selected and subjected to strict quality tests. This ensures the production of high-quality vibrating screens while keeping costs under control.

Innovations to increase efficiency include automatic maintenance alert systems and remote monitoring of machines. This makes it possible to take preventive measures before any breakdown occurs. In addition, with smart systems, the operating conditions of machines can be continuously optimized. For example, the vibration frequencies of the screens can be adjusted according to material properties. This provides an important advantage in achieving maximum efficiency at every stage of production.

Excellent Results with Customized Solutions in Industrial Vibrating Screen Production

In industrial production processes, every business has different needs and requirements. Therefore, customized solutions provide excellent results by offering business-specific designs and functional systems. Vibrating screens also achieve significant performance improvements through such customized solutions.

Customized designs play a critical role in meeting specific industrial needs. For example, a vibrating screen produced for a food processing plant can be designed to be compatible with different materials, while one produced for a construction materials manufacturer can be equipped with more durable components. Such customizations respond in the most appropriate way to the needs of both industries.

These customized solutions not only increase production speed but also optimize costs. In addition, customer-oriented designs allow longer use with fewer errors and less maintenance. This helps businesses run a more efficient and sustainable production process.

Customized vibrating screen systems can also be equipped with smart features that increase efficiency. For example, users can remotely monitor their machines and make adjustments when necessary. Such innovative features ensure that the production line operates continuously under optimal conditions.

The innovative technologies used in vibrating screen production increase efficiency, while customized solutions play a critical role in meeting the different needs of each industry. For excellent results, these technologies and solutions are constantly evolving and shaping the industry.