Roller conveyors are industrial systems used to transport products on a horizontal plane. These conveyors are commonly used in large-scale transportation and logistics operations, assembly lines, and manufacturing plants. The working principle is quite simple: the load-bearing products are moved from one point to another by sliding over a series of cylindrical rollers. These rollers are usually made of metal, plastic, or rubber and are the core components of the conveyor system.

So, why are roller conveyors so widely used? First of all, their durability and ability to carry even heavy loads make them indispensable across different industries. Additionally, their low maintenance costs ensure long-lasting operation. However, each industry requires a different roller conveyor solution because the characteristics of the products being transported directly affect the conveyor’s design.

Basic Structure and Working Principle of Roller Conveyors

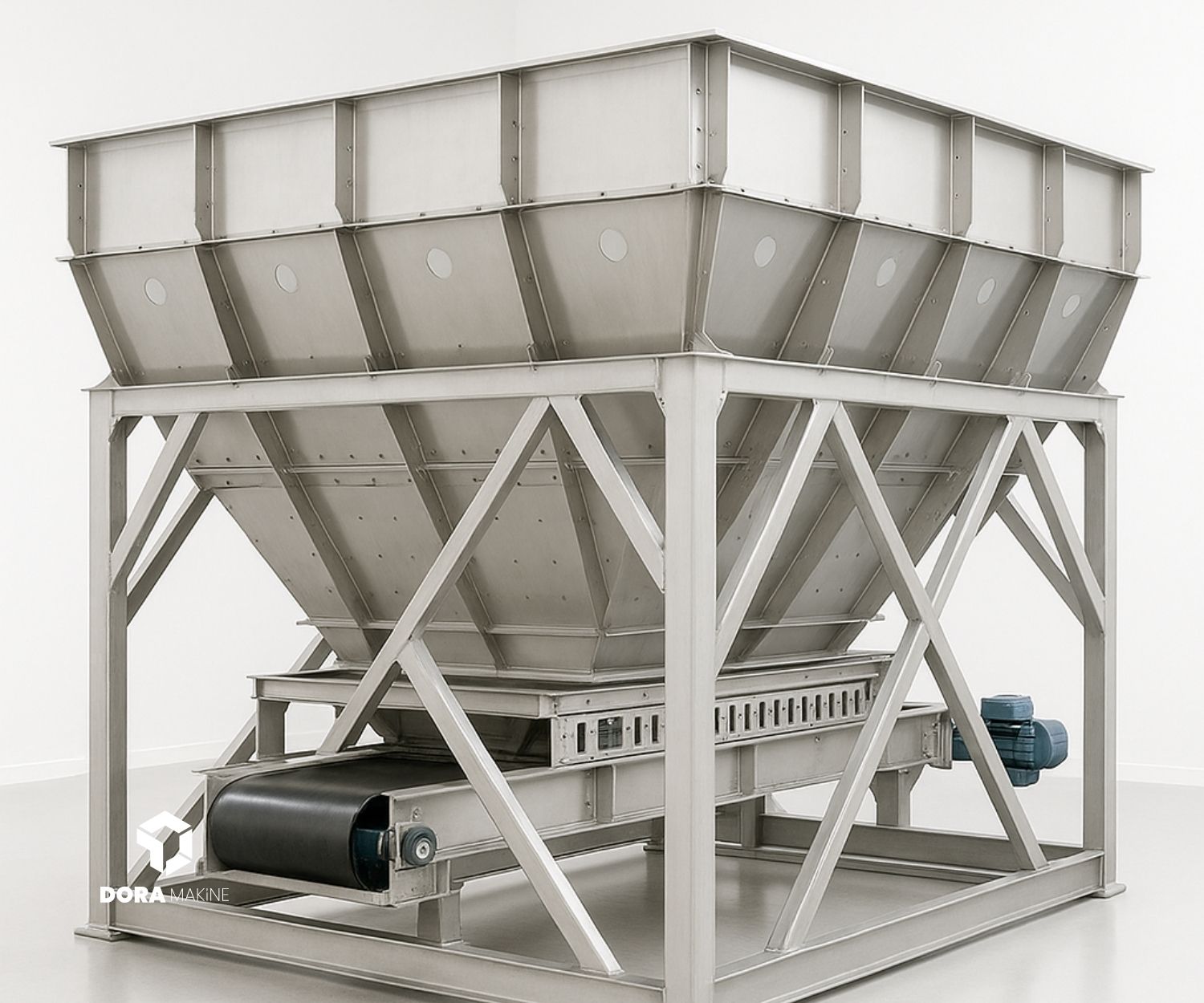

Roller conveyor systems consist of several main components: rollers, frame, motor, belts, and carrying elements. Each of these parts is critical for the conveyor’s efficient operation. Essentially, the rollers move the products horizontally, while the frame guides this movement safely. The motor, usually electric, provides the kinetic energy to rotate the rollers.

The working principle of roller conveyors is quite straightforward. After a product is placed at one end, it is transported by the movement of the rollers driven by the motor. Due to their cylindrical shape, the rollers allow the products to slide and move. Moreover, the conveyor’s speed and carrying capacity depend on factors such as motor power and the number of rollers. Therefore, customized conveyor systems are used for transporting different types of products.

Technically, roller conveyors are designed to ensure products are moved safely and efficiently. However, the ideal roller types differ depending on the industrial application. For example, conveyors used in the food industry must comply with hygiene standards and ensure that food products are transported without damage. On the other hand, conveyors used in the automotive industry are designed to carry heavier and larger parts. The design of roller conveyors can be tailored to such varying needs.

Industrial Applications of Roller Conveyors

Roller conveyors are widely used across many industries, especially in automotive, food, electronics, pharmaceuticals, and textiles. In the automotive industry, roller conveyors are one of the main transportation systems used in car assembly lines. These systems move automotive parts from one point to another and speed up the production process.

In the food industry, roller conveyor systems are specially designed for hygienic and safe transport. To prevent food products from turning into liquid or powder form, the materials and surface designs are carefully chosen. In the electronics industry, roller conveyors play an important role in moving sensitive parts with precision and vibration-free operation.

In the textile industry, roller conveyors make it easier to transport fabrics and garments. These systems ensure uninterrupted workflow during production while also increasing production speed. In these industries, conveyors are typically designed to withstand heavy loads and have a long lifespan. So, what are the fundamental reasons for their use across so many industries? Factors such as efficiency, speed, and low maintenance costs make roller conveyors highly attractive.

Types of Rollers Used in Roller Conveyor Systems

The rollers used in roller conveyor systems are critical for the transport process. Roller types vary depending on the type of product being moved and the transport conditions. The most common roller types include metal rollers, plastic rollers, and rubber rollers. Metal rollers are preferred for heavy loads, while plastic rollers are more suitable for lighter products. Rubber rollers, on the other hand, are used to prevent slipping and are generally preferred for sensitive transport.

Selecting the right type of roller ensures conveyor efficiency and durability. For example, strong steel rollers are usually chosen for transporting heavy metal products. Plastic rollers are more common in the food industry and for light loads, as they are more resistant to corrosion and easier to clean. Choosing the right roller type for each industrial application is essential for effective system operation.

The choice of roller depends not only on carrying capacity but also on transport speed and environmental factors. For example, rollers with higher friction resistance may be preferred for products transported at high speeds. Furthermore, each roller has a different load capacity. Therefore, accurately determining the carrying capacity during the design phase is crucial.

Carrying Capacity and Speed Management in Roller Conveyors

The carrying capacity and speed management of roller conveyors are vital for efficient operation. The carrying capacity determines the maximum load the conveyor can handle. This capacity depends on factors such as the size of the rollers, motor power, and frame structure used in the conveyor design. Determining the correct carrying capacity prevents system overload and ensures a longer lifespan.

Speed management refers to controlling the speed at which products are transported. This is especially important for products requiring delicate handling. Speed control is usually achieved through motor power and driver systems. Speed management also affects the energy efficiency of the conveyor system. A system running at low speed can reduce energy consumption, though it may also limit carrying capacity.

The balance between speed and capacity management in roller conveyors ensures efficient operation. Excessive speed can damage products, so the right speed and carrying capacity must be defined for each application. Optimizing speed and carrying capacity saves time in production processes while also minimizing energy costs.