Silo manufacturing plays a critical role in industrial production and storage areas. The materials used in this process directly affect the durability, safety, and efficiency of the silo. In addition to traditional materials such as steel and concrete, new materials made possible by advancing technology in recent years have also gained an important place in this sector. In this article, we will discuss the materials used in silo manufacturing, technological methods, and the advantages of these materials.

Commonly Used Material Types and Their Properties in Silo Manufacturing

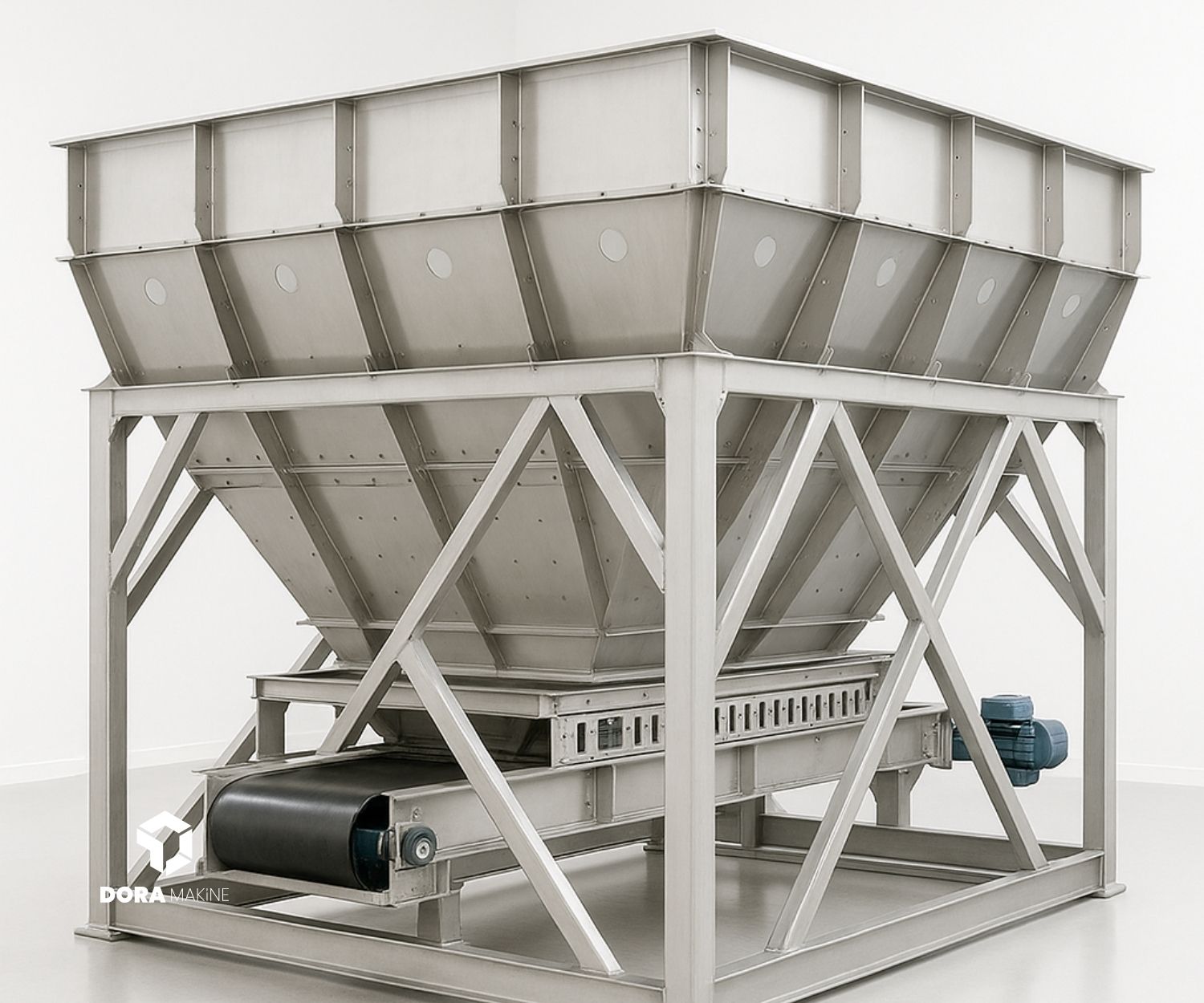

Among the most commonly used materials in silo manufacturing are steel, concrete, and composite materials. Each material offers advantages and disadvantages depending on the purpose of use, the size of the silo, and the type of product stored.

- Steel: Steel silos are known for being durable and long-lasting. Steel material is particularly preferred in applications that require high strength and flexibility. One of the biggest advantages of steel silos is their high resistance to external factors, maintaining their form for long periods. Steel also enables faster manufacturing and requires less maintenance compared to concrete structures.

- Concrete: Concrete silos are especially preferred for large capacity requirements. Concrete stands out with its load-bearing capacity and sound insulation properties. Additionally, concrete is often more cost-effective. However, the manufacturing process of concrete silos takes longer, and their maintenance needs are higher compared to steel silos.

- Composite Materials: Composite materials, which are a combination of steel and concrete, offer a lighter and more durable structure. These materials are often used in storage environments exposed to aggressive chemicals. Composite materials are especially resistant to corrosion and provide long-lasting structures. However, their costs may be higher than traditional materials.

The choice of these materials is largely influenced by factors such as the storage environment, load capacity, and budget. Which material will be used should be optimized based on the silo’s design and functionality.

Differences and Advantages of Steel and Concrete Silo Manufacturing

Although steel and concrete silos differ primarily in terms of building material, both are widely used in silo manufacturing. So, what are the differences between steel and concrete silos, and in which situations should each be preferred?

Steel silos are especially preferred in industrial production processes due to their fast installation and flexibility. Steel is not only cost-effective but also quicker to construct, with less time-consuming maintenance. Steel silos are generally used for small- and medium-scale storage needs. Another advantage of steel silos is their ease of maintenance. Additionally, steel is highly resistant to weather conditions and external impacts.

On the other hand, concrete silos are chosen for larger-scale projects. Concrete, with its high load-bearing capacity and long-lasting structure, is an ideal choice for industries requiring large amounts of storage. Concrete silos are generally built with much larger diameters and higher capacities. However, the construction process of concrete takes longer than steel and requires more labor. Furthermore, concrete can be more expensive than steel. The advantage of concrete silos lies in their high security and durability, though their long construction times make them unsuitable for urgent needs.

Advanced Welding Technologies and Their Impact on the Manufacturing Process

In recent years, welding technologies used in silo manufacturing have also undergone a major transformation. Welding technology plays an important role in the manufacturing of steel silos. Advanced welding technologies allow silos to be produced faster and more safely. For example, with automated welding machines, welding processes can be carried out more quickly and precisely. This not only accelerates the production process but also improves quality.

Developments in welding technology also provide advantages in terms of energy efficiency and cost reduction. Producing with less energy and labor contributes to the competitive structure of the sector. Additionally, advanced welding technologies improve the sealing properties of silos, offering safer and more efficient storage solutions.

Durability and Safety Standards in Silo Design

One of the most critical factors in silo design is durability and safety standards. In silo design, every stage from material selection to manufacturing processes is shaped with these two elements in mind. Industrial storage areas may be exposed to many external factors, from harsh weather conditions to high load-bearing requirements. Therefore, durability and safety are top priorities during silo design.

Durability is an important factor that ensures the silo can be used safely for many years. At this point, material selection aims to extend lifespan and reduce maintenance costs. Safety standards, on the other hand, come into play in cases of storage capacity overload, risk of spoilage of stored products, or hazards such as fire. Various safety measures and systems are integrated into silo design to prevent such adverse situations.

For example, for fire safety, heat-resistant materials are used, and fire suppression systems are integrated to minimize fire risks. At the same time, special measures are taken against natural disasters such as earthquakes. For durability, the combination of concrete and steel materials is frequently preferred.

These safety measures and durability standards in silo design directly affect the long-term success of industrial enterprises. A safe and durable silo provides efficient storage, low maintenance costs, and high performance for the business.