Types of Materials Commonly Used in Bunker Manufacturing and Their Properties

Bunkers are critical structures in military, industrial, and civilian fields, manufactured with a variety of materials and technologies. These materials are carefully selected to ensure the durability, safety, and efficiency of bunkers. In addition to traditional materials such as steel and concrete, technological innovations in recent years have revolutionized bunker production. In this article, we will examine in detail the main types of materials used in bunker manufacturing, their properties, and the technological advancements in the field.

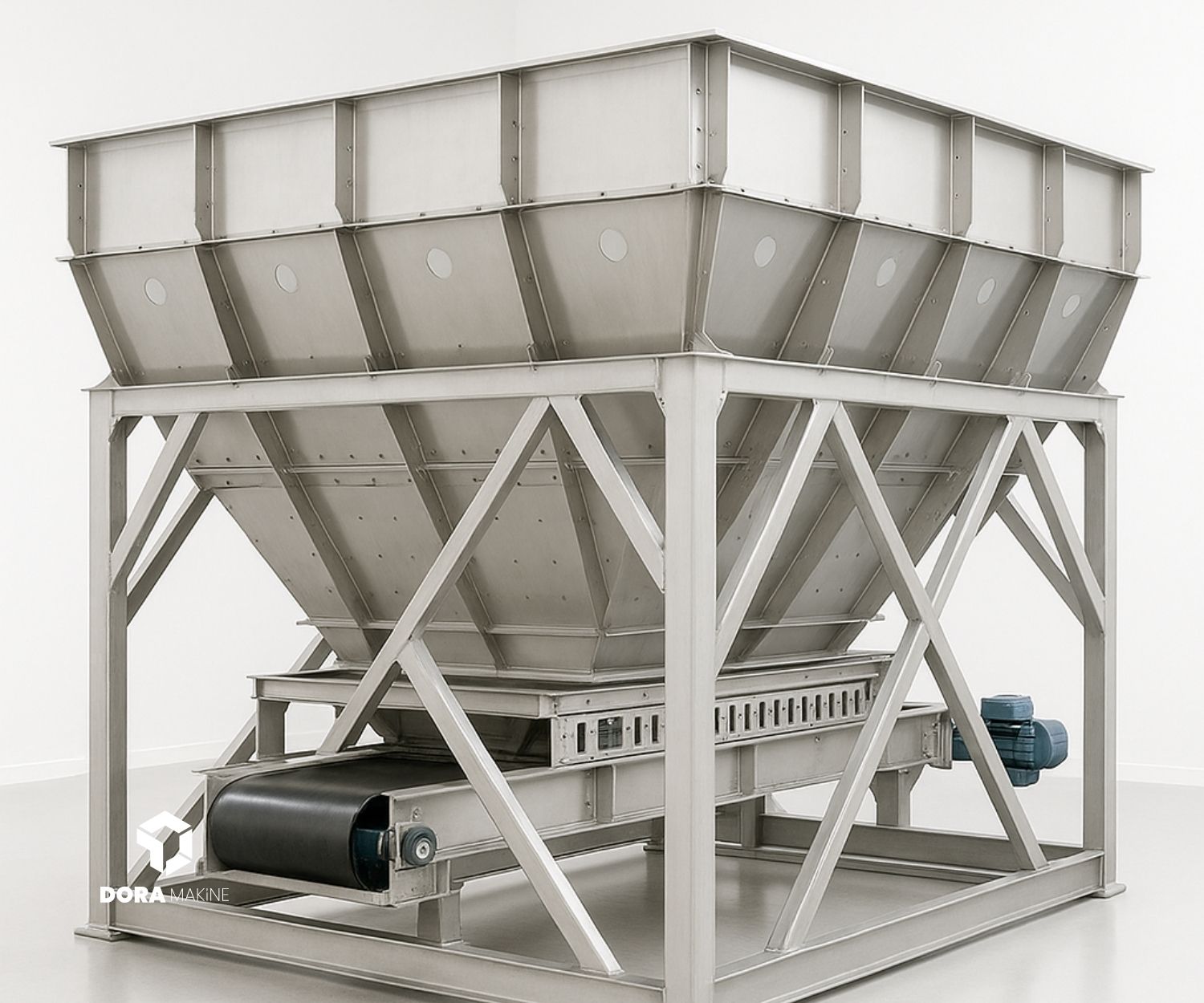

The materials used in bunker construction are one of the factors that directly affect the durability of the structure. The most commonly used material types are as follows:

- Steel: Steel offers high durability and safety. In addition to being resistant to explosions, it makes the structure lighter. Steel bunkers also provide flexible interior design possibilities, allowing the creation of various functional spaces.

- Concrete: Concrete bunkers have a high load-bearing capacity and provide superior protection. Compared to steel, it may be more costly but is often preferred in large-scale projects. With its high strength, concrete is one of the fundamental components of reinforced concrete structures.

- Composite Materials: Composite materials are increasingly preferred in modern bunker manufacturing because they are durable and lightweight. These materials, combining steel and concrete, save resources, shorten production time, and increase energy efficiency.

So, which type of material is more advantageous? Considering the differences between steel and concrete, it is necessary to analyze in more detail their areas of use and advantages. Steel provides faster assembly and lightness, while concrete forms the foundation of a stronger structure. Both materials can be optimized according to different needs.

Technological Developments in Steel and Concrete Bunkers

Traditional bunker manufacturing relied mostly on the use of materials such as steel and concrete. However, in recent years, significant innovations have emerged in the technologies used to process these materials. These advancements not only reduce production costs but also make bunkers more durable and secure.

For example, in steel bunkers, robotic welding technologies are being used to achieve faster and more precise production processes. This minimizes errors at steel joints and increases the overall safety of the structure. In concrete bunkers, 3D printing technology has started to be used. This technology allows concrete pouring to be carried out more quickly and accurately, thus shortening construction time and reducing labor costs.

Adopting these technologies provides significant advantages for bunker manufacturers, especially in large projects. These innovations in the processing of steel and concrete not only increase production speed but also enable the construction of more durable and efficient bunkers. So, what are the long-term effects of these technologies? It is expected that these innovations will become more widespread in the future, both in terms of cost efficiency and the lifespan of the structures.

High-Strength and Protective Coating Materials

The equipment and people inside bunkers must be protected against external threats. For this reason, the quality of the coating materials used on the outer surfaces of bunkers is of great importance. High-strength and protective coatings not only enhance bunker security but also extend their lifespan.

Ceramic coatings are durable materials used on both the interior and exterior surfaces of bunkers. These coatings provide superior protection against high temperatures and mechanical impacts. They also protect steel against corrosion. In addition, epoxy-based coatings are another option that increases bunker durability, offering high protection especially in acidic and alkaline environments.

We mentioned that the outer surface of bunkers must be durable. But are these coatings used only against external threats? No, coating materials also help regulate humidity and temperature inside the structure, protecting the equipment within. A well-chosen coating material can also improve energy efficiency.

Digitalization and Automation Technologies in Bunker Manufacturing

In recent years, the use of digitalization and automation technologies has created a major revolution in bunker manufacturing, just as in many other industries. These technologies optimize production processes, allowing faster, more efficient, and error-free manufacturing. Especially in large-scale projects, their use saves time at every stage of production while improving quality.

IoT (Internet of Things) technology has emerged as a key innovation in bunker production. This technology connects every machine on the production line, making it possible to monitor their real-time status. In this way, potential production disruptions can be detected earlier and addressed more quickly. Moreover, production systems equipped with artificial intelligence enhance process efficiency while minimizing human error.

So, how does digitalization make a difference in bunker construction? Digitalization allows better tracking and coordination in project management, while increased efficiency in the production process leads to higher-quality outcomes. Automation reduces the need for physical labor, allowing people to take on more strategic roles. It is undeniable that these technologies will play an even greater role in bunker manufacturing in the future.

In conclusion, technological innovations in bunker manufacturing make production faster, more efficient, and safer. Along with traditional materials like steel and concrete, composite materials and coating technologies also play an important role in bunker production. With the impact of digitalization and automation technologies, every stage of production is being managed more intelligently, resulting in more durable bunkers. Industry professionals expect these technologies to become even more widespread in the coming years.