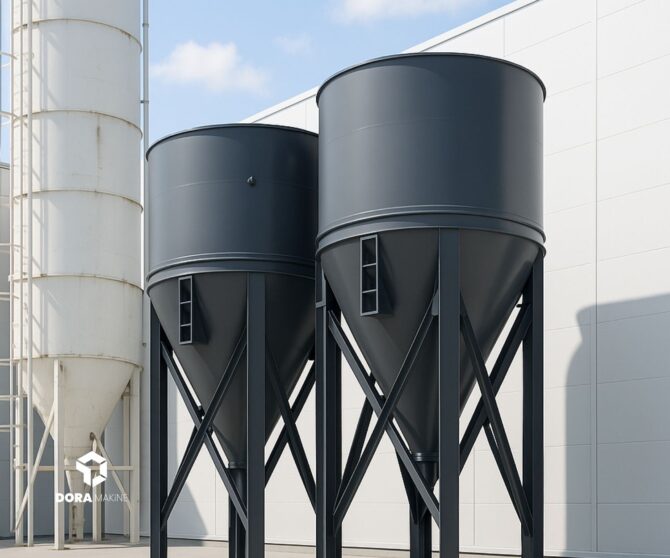

Dora Makine Quality Silo Manufacturing

As Dora Makine, we are a company specialized in the manufacturing of silo systems that enhance efficiency and ensure consistent quality in industrial production processes. By using advanced technology and high-quality materials, we manufacture long-lasting and reliable silo systems in compliance with industry standards.

Standard Features

Dora Makine’s silo systems are designed in compliance with the highest quality standards. The main standard features of our products include:

- Complete AISI 304 Stainless Steel Structure: Our silos are manufactured from stainless steel, providing a durable and long-lasting solution.

- Different Diameter Options: We offer designs with diameters of 2, 2.5, or 3 meters to deliver customized solutions for different needs.

- Bolted Modular Design: Our silo systems feature a modular structure, allowing easy and fast installation. The modular design also makes maintenance and repair practical.

- Fluidized Air Cushioning System: Ensures better preservation and more efficient storage of products inside the silo.

- Airlock System and Flour Discharge: Equipped with an advanced airlock system to ensure safe and uninterrupted flour discharge.

- PLC-Controlled Command System: Provides easy control and monitoring with a PLC-based control system.

Optional Features

To offer tailored solutions to customer needs, our silo systems include various optional features. These options provide more efficient and optimized storage solutions:

- Vibration Cone: Improves flour flowability, making product transfer inside the silo more efficient.

- Jet Filter System: Ensures product cleanliness and maintains a healthy environment, available as an optional feature.

- Automatic Silo Weighing System: Allows easy monitoring of product quantity and precise process management with automatic weighing.

- Automatic Integration with Flour Weighing Stations: Enables automatic loading and weight control with integrated flour weighing stations.

- Bag Loading with Sieving System: Provides more accurate and clean loading by sieving flour during bag usage.

- Inline Sieve and Magnetic Separation Systems: Ensure better flour separation, allowing you to achieve higher-quality end products.

Dora Makine stands out in industrial silo manufacturing by offering solutions that deliver high quality and durability. Our silo systems, produced using AISI 304 stainless steel, are long-lasting, corrosion-resistant, and meet the strict hygiene requirements of the food industry. Innovative features such as fluidized air cushioning and PLC-controlled command systems make product storage and transfer more efficient, while optional components like vibrators and jet filter systems further enhance system performance. Thanks to their modular design, our silo systems provide fast installation, easy maintenance, and customized solutions with diameter options of 2, 2.5, or 3 meters.

In silo production, Dora Makine ensures high efficiency, cost savings, and flexibility. Silobus connections eliminating bag costs and reduced labor in handling lower operational expenses for businesses. Our expert team carefully manages each project, developing solutions tailored to specific customer needs. In addition, we provide technical support and maintenance services after installation, ensuring long-term and uninterrupted operation of the systems.

Quality and Durability: Stainless Steel Storage

Stainless steel is one of the most durable and long-lasting materials for industrial storage solutions. High-quality stainless steel resists various weather conditions and chemical effects. This makes stainless steel a preferred material in the food, pharmaceutical, and chemical industries. Manufacturers choose stainless steel storage systems to maintain the health and safety of their products.

Stainless steel storage units also provide cost-effectiveness due to their durability. Stainless steel silos, which can be used for many years, reduce long-term maintenance costs. However, alongside its advantages, stainless steel requires regular maintenance. So, how can the maintenance of stainless steel storage systems be optimized? Regular cleaning and assembly maintenance ensure long-lasting performance.

High Efficiency: Fluidized Air and PLC Systems

Efficiency is a critical factor, especially in industrial production processes. Fluidized air systems are used in storage areas for ventilation and temperature control. These systems optimize airflow within the storage environment and maintain the balance of temperature and humidity. When combined with PLC (Programmable Logic Controller) systems, they make storage processes more efficient through automated control mechanisms.

PLC systems are highly effective for data tracking and automated management. They allow real-time monitoring of machine operating times, maintenance needs, and storage conditions. This minimizes downtime and production errors. Integrating these technologies into a storage environment boosts operational efficiency while reducing business costs. Although installation may initially be costly, how is long-term return on investment achieved? Forward-looking savings are possible with proper system installation.

Modular Designs: Custom Silo Solutions

Modular designs offer flexible and customizable storage solutions. In large-scale industrial plants, modular silo solutions provide advantages such as quick installation and easy transportability. These designs maximize storage space efficiency and help avoid unnecessary costs.

Custom silo solutions can be designed with high capacity and tailored to specific storage needs. So, how can modular designs be made even more efficient? Flexible storage spaces can include silos of different sizes and shapes for every type of product. This ensures that storage solutions meet the unique needs of each business. In addition, modular systems are faster and more cost-effective to assemble, as each component can be manufactured separately and transported to the installation site.

Cost Savings: Eliminating Bag Costs

Bag use is a significant cost factor in many industries. In the food and chemical sectors, bags are widely used for storing and transporting liquid and powder products. However, both the costs and environmental impacts of bags can be eliminated with alternative solutions. One of the most effective ways to eliminate bag costs is through closed storage systems. These systems allow products to be transferred directly into silos without the need for intermediate packaging like bags.

Closed systems not only enhance product safety but also make storage and transportation more efficient. At the same time, they can be considered environmentally friendly practices. So, how can bag use be reduced? Switching from bag use to bulk storage and transportation systems significantly reduces costs in the long run. Additionally, such systems cause less harm to the environment.

Expertise and Support: Installation and Technical Service

The installation and maintenance of every storage system require expertise. Industrial-scale storage solutions are systems that demand high technical knowledge and experience. For this reason, obtaining professional installation and technical service support is critical to ensuring the right solution and efficient system operation.

Reliable installation and technical service guarantee that the system works properly from the start. They also help maintain high performance during maintenance and repair processes. So, how can such services be chosen? Trustworthy, certified experts and high-quality service providers ensure successful results during both installation and maintenance. The long-term benefits of professional services for industrial storage systems far outweigh the investment.