Silo Manufacturing: A Fundamental Component of Industrial Storage and Handling

Silo manufacturing forms the backbone of material storage and handling processes in industrial facilities. This process consists of a series of complex steps, ranging from a carefully planned design phase to high-quality production processes and precise installation. Silo manufacturing must be managed correctly to improve workforce efficiency, ensure safety, and maintain the operational continuity of the facility. So, when analyzing this process step by step, which elements stand out the most?

Silo Design Phase: Needs Analysis and Project Planning

Silo design is the first step, where factors such as functionality, safety, and efficiency are meticulously considered. The design process begins with an analysis of the needs of the site where the silo will be constructed. In the first step, the type of material to be stored, capacity requirements, environmental conditions (such as climatic factors), installation site, and intended purpose are determined. This phase lays the foundation for a durable and efficient silo design in the long run. For example, silos for the food industry can differ significantly from those for the construction industry. So, in silo design, which parameters might be more important? Capacity, or safety measures?

Needs analysis and project planning are critical for the sustainability of silo design. Correct choices made in this stage minimize potential issues in production and installation. The most important considerations in the design phase are the structural durability of the silo and the correct determination of storage capacity. For instance, if the silo capacity is miscalculated, it may lead to overloading and difficulties in material handling. Designers must consider best engineering practices at this stage.

Material Selection and Technological Preparation for the Manufacturing Process

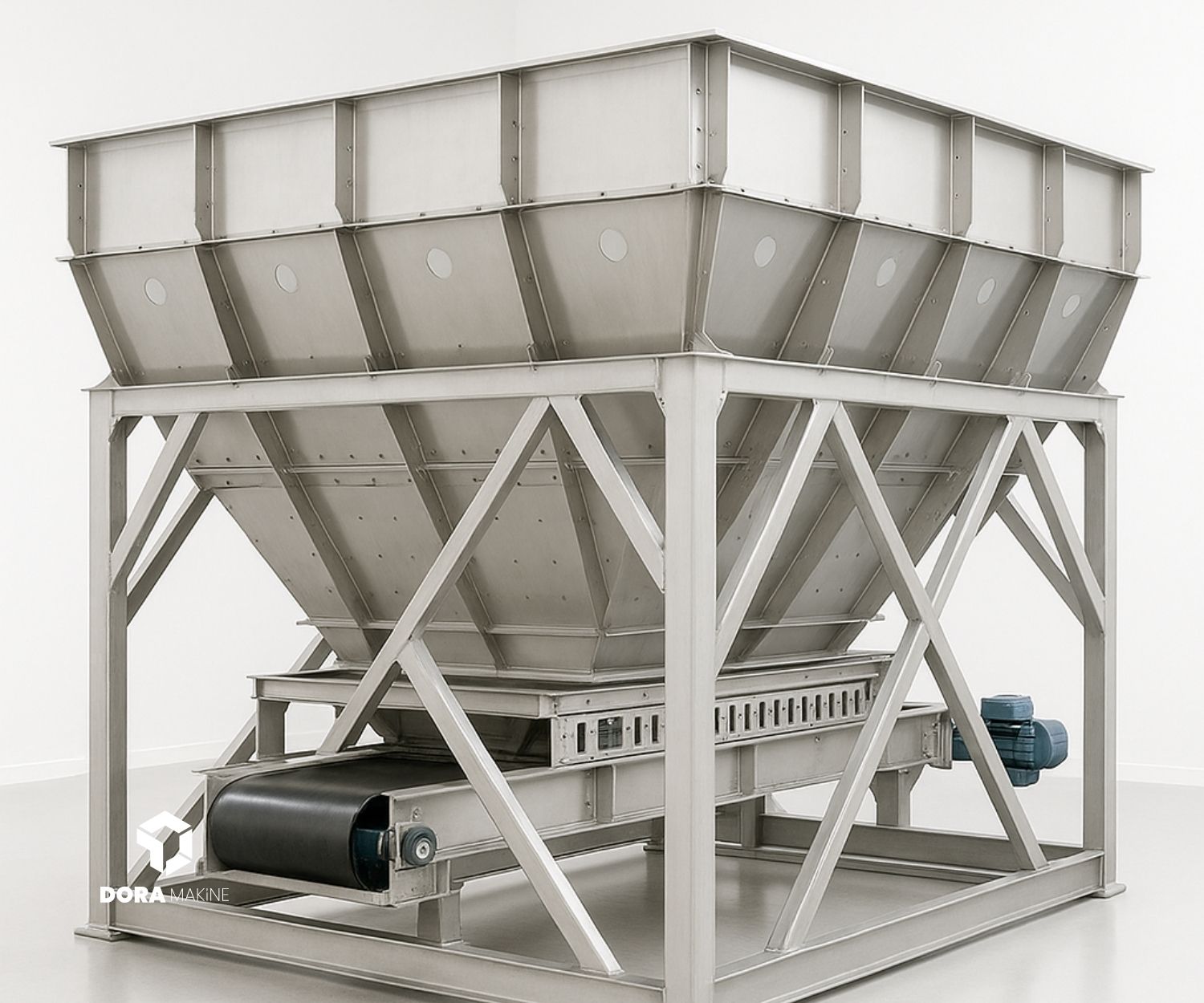

Silo manufacturing is directly linked to the right choice of materials and production process. Silos are typically produced from durable materials such as steel, concrete, or aluminum. Each material has its advantages and disadvantages. For example, steel silos are long-lasting and can carry heavier loads, while concrete silos are generally more resistant and less affected by temperature changes. Material selection depends on the environment in which the silo will be used and the type of material it will store. However, material selection should not focus solely on durability. Environmental impacts during production, costs, and workforce requirements must also be considered.

Before starting production, technological preparation is crucial. Automated machinery used in modern silo manufacturing saves both time and costs. At every stage of production, quality control must be ensured through precise cutting, shaping, and assembly, supported by these technologies. Additionally, industrial software plays a vital role in both design and production stages. With accurate measurements and calculations, these tools ensure error-free manufacturing. A strong technological infrastructure directly affects the quality of production and ensures the creation of a safe silo.

Silo Installation: Logistics and Communication Strategies

Silo installation is the most important stage following design and production. This phase involves correctly assembling the silo components on-site. The installation process requires proper logistics and communication strategies. Materials must arrive at the installation site in the right order and at the right time. Strong communication among on-site teams is also essential. So, what are the biggest challenges that can arise during silo installation? Workforce, time management, and logistical setbacks are the key factors affecting this stage.

Logistics strategies should be optimized to ensure that silo components arrive at the site on time. A good logistics plan ensures smooth progress in the installation process. The proper selection of equipment and tools also speeds up installation. Uninterrupted communication on-site enables quick resolution of problems at every stage of installation. Therefore, engineers and technicians working on-site must establish an effective communication network. Success in the installation phase often depends on how well logistics and communication are managed.

Quality Control and Testing Phases: Safety and Performance Tests

The final stage of silo manufacturing involves quality control and testing. Silos must be not only functional but also safe. Therefore, post-production quality control tests are mandatory. The materials used in manufacturing must comply with quality standards. Additionally, after installation, performance tests should be conducted to verify durability, load-bearing capacity, and safety.

Safety tests are among the most critical factors in silo installation. Depending on the type of material stored, silos can carry high risks. Thus, accurate measurement of capacity and testing of durability are essential. Performance tests also confirm the functionality of the silo. During these tests, every component inside the silo is inspected for reliability. For example, blockages within the silo could hinder material flow and reduce efficiency. Such issues must be identified during testing. So, which tests best assess silo durability? Load-bearing tests and simulation tests are the primary ones.

In conclusion, the silo manufacturing process is a complex operation that must be managed with great care. Each stage requires high attention to technical and logistical detail. High-quality material selection, precise installation, effective communication, and strict quality control tests form the foundation of successful silo production.