Vibrating screens hold an important place in industrial production processes. They are generally used in critical stages such as separation, screening, classification, and filtration. Vibrating screens, which are especially used to separate particle sizes, select specific materials, and increase efficiency, have become one of the indispensable technologies in many industrial fields. In this article, the role of vibrating screens in industrial processes, their importance, and the impact of this technology in different fields will be examined in detail.

Definition of Vibrating Screen Technology and Analysis of Its Critical Components

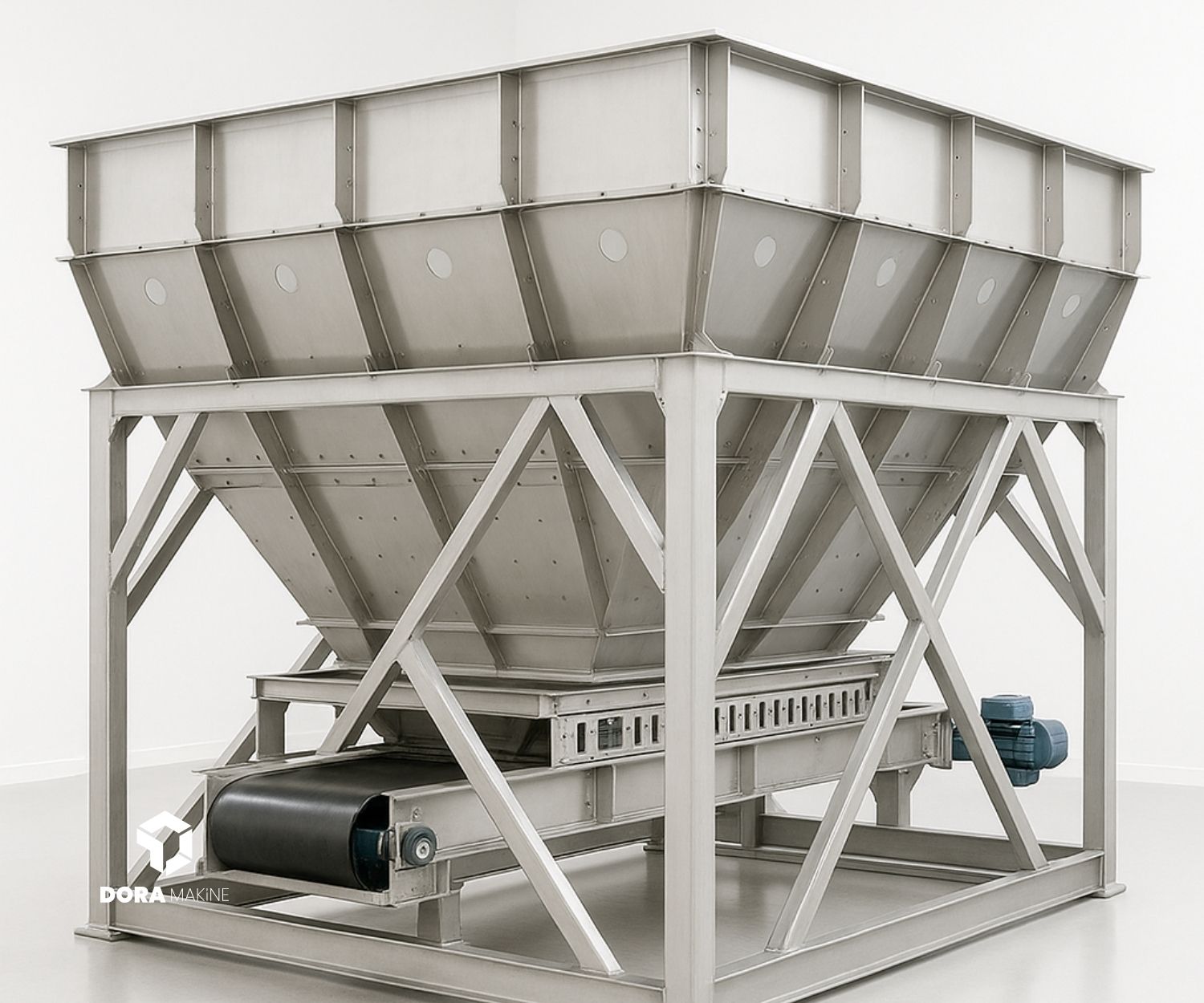

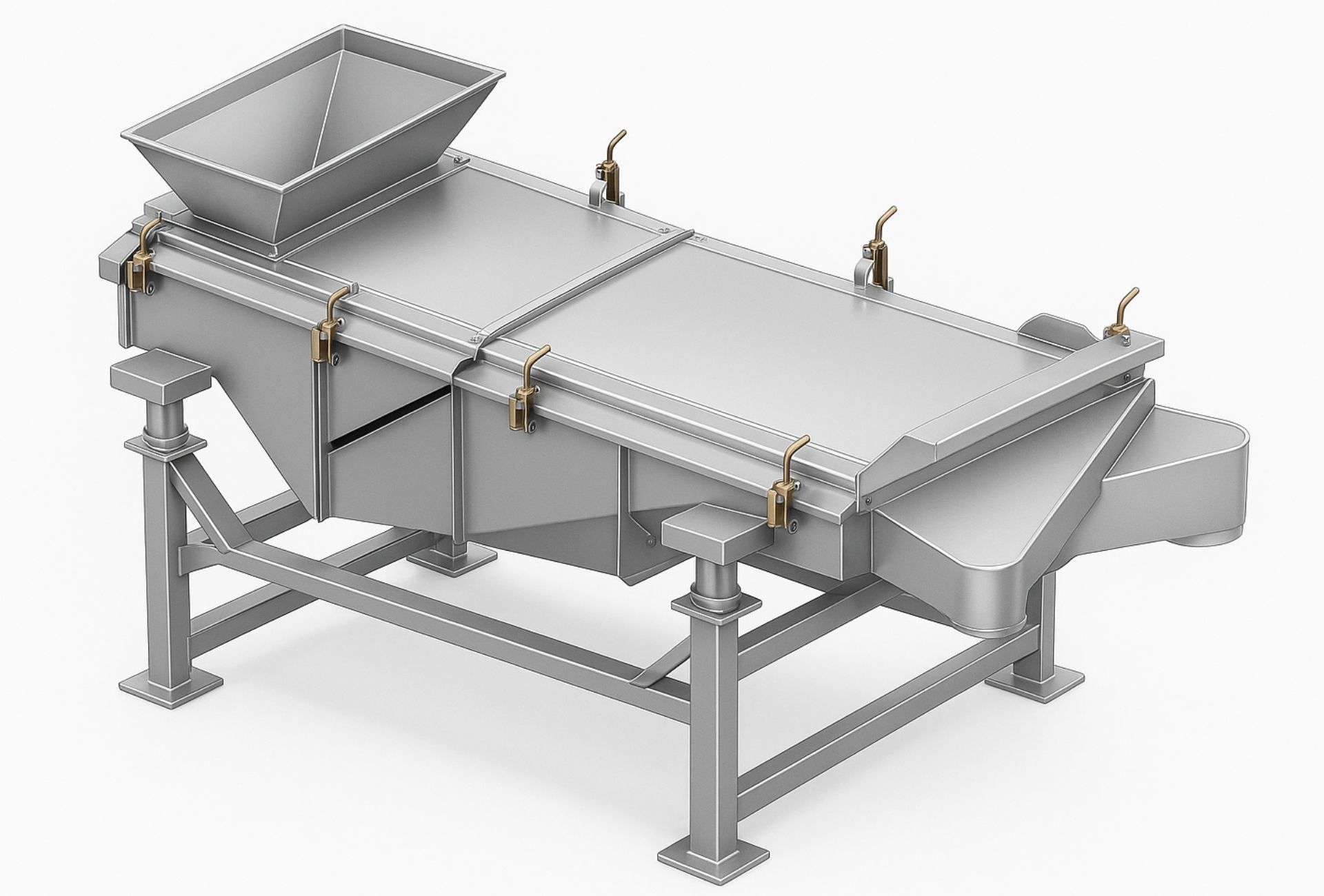

Vibrating screens generally function by separating materials through vibration movement on a surface. This technology is particularly used in solid-particle separation processes and has a wide range of applications in the food, mining, construction, and chemical industries. The working principle of vibrating screens allows materials to move at different speeds on the screen surface due to vibrations, thus separating particles of different sizes. So, what are the components that make this technology unique?

The main components of vibrating screens include screen surfaces, vibration motors, springs, and supporting systems. Each of these components plays a critical role in the efficient operation of the system. In particular, the power of the vibration motors directly affects the performance of the screen. Strong motors enable faster and more effective separation processes. In addition, the angles and slopes of the screen surface determine how the particles will be separated. The correct selection of these components is very important for increasing the efficiency of vibrating screens.

Vibration Dynamics and Particle Separation Mechanism: Working Principle

To understand the working principle of vibrating screens, it is necessary to take a closer look at vibration dynamics. Vibrating screens operate on a vibrating platform powered by an electric motor. These vibrations continuously move the particles on the screen surface. This process allows particles to be separated based on their sizes and shapes. Smaller, low-density particles pass quickly through the screen surface, while larger or denser particles move more slowly and are separated.

However, the efficiency of this mechanism does not depend solely on vibration frequency and amplitude. The inclination of the screen surface must also have the correct angle to allow particles to pass through efficiently. For this mechanism to work properly, the vibrations must be controlled regularly and accurately. Vibrating screens are designed to allow particles to be separated at different layers. High-performance screens apply this dynamic in the most efficient way, offering greater production capacity.

Design Parameters and Configuration Strategies that Enhance Process Efficiency

The potential of vibrating screens to improve industrial efficiency is directly related to the right design parameters and configuration strategies. So, which design factors can increase efficiency? First of all, the design of the screen surface is an important factor. The type of material used on the surface and its compatibility with the materials to be processed play a key role in the separation process. High-quality materials provide long-lasting performance, especially in industries working with abrasive substances.

Secondly, the adjustability features of the screens are important. In industries where various material types and sizes are processed, the operating speeds and vibration frequencies of the screens should be adjustable. Adjustable vibration speed ensures optimum performance according to different processing requirements. This feature helps processes run faster and reduces material losses to a minimum.

Finally, the efficiency of the systems in which the screens are integrated also has a significant impact. The harmonious operation of electrical, mechanical, and thermal systems will increase overall efficiency. For this reason, system compatibility must be taken into account in screen design.

Industrial Application Areas: Value Proposition from Mining to Food Processing

Vibrating screens have a wide range of applications, from mining to food processing. In the mining industry, they are widely used for mineral separation and fine particle screening. In mines, the separation of minerals of different sizes is directly related to the success of vibrating screens. These screens perform mineral separation very effectively with high efficiency and low energy consumption.

In the food processing industry, vibrating screens are particularly used in flour and sugar processing. Purifying and properly sizing food products play a critical role in improving product quality. In flour production, vibrating screens help separate milled grains into the appropriate sizes. This technology also removes unwanted foreign materials from food products, thus improving the quality and safety of the product.

These two industrial fields demonstrate the efficiency and versatility of vibrating screens. So, in which other fields can this technology be used? The potential of vibrating screens is also quite high in industries such as textiles, chemicals, and automotive.

Operational Maintenance Approaches, Safety Procedures, and Life Cycle Cost Optimization

The operational efficiency of vibrating screens is not limited to design; it must also be supported by proper maintenance and safety procedures. Maintenance of electric motors, monitoring of vibration levels, and regular cleaning of surfaces ensure the longevity of the screens. In addition, the use of proper lubrication techniques and component replacement schedules during maintenance increases the efficiency of the equipment.

Safety procedures are important to ensure the operational safety of vibrating screens. Proper installation of vibrating systems and protective measures prevent workplace accidents and create safe working environments. Operators working with vibrating screens must undergo special training for using such machines. Furthermore, monitoring vibration levels prevents structural damage that can be caused by excessive vibrations.

Finally, life cycle cost optimization plays a major role. The longevity of vibrating screens reduces operating costs and shortens the return on investment period. Therefore, maintenance costs must be calculated accurately, and equipment must be monitored regularly. Additionally, energy efficiency should be considered; energy-saving screens offer significant cost advantages in the long term.

Vibrating screens are indispensable tools for increasing the efficiency of industrial processes and optimizing separation operations. Vibration dynamics and particle separation mechanisms form the foundation of this technology. With the right design parameters and maintenance approaches, vibrating screens can increase efficiency in many industries. From mining to food processing, the role of this technology is significant across a wide application spectrum. Finally, life cycle cost optimization and safety procedures further enhance the effectiveness of these machines. In conclusion, the role of vibrating screens in industrial processes ensures that operations become faster, more efficient, and safer.