What Are Conveyor Systems?

Conveyor systems are mechanical systems that enable the transportation of a product or material from one point to another. These systems are commonly used in production lines, storage areas, logistics centers, and distribution facilities. Conveyors automate material handling processes in various industries, reducing labor costs and increasing operational efficiency. The design of conveyor systems varies depending on the type, quantity, and distance of the material to be transported.

So, what is the basic operating principle of conveyor systems? Essentially, these systems consist of a component that moves on a transport surface driven by a motor. This surface can typically be a belt, chain, or another conveying element. For these systems to operate quickly, safely, and effectively, proper design and appropriate maintenance are required.

Definition and Basic Operating Principle of Conveyor Systems

Conveyor systems play a major role in industrial production and transportation processes. These systems ensure the movement of materials or products along a defined route. The basic operating principle generally involves a motor-driven surface that carries materials and advances along a fixed route. These surfaces can come in various types. For example, a belt conveyor system usually has a flat transport surface, whereas roller conveyors use cylindrical structures.

The fundamental design of conveyors not only ensures safe and fast transportation but also improves efficiency. For example, in a production line, thanks to a conveyor system, materials can be automatically moved from one point to another without the intervention of operators or machines. This saves time and reduces operational errors.

Moreover, the operating principle of conveyor systems can be customized according to the type of material to be transported. For instance, in a facility where heavy loads are carried, the motor power and transport surface are specially reinforced. On the other hand, more careful handling mechanisms may be required for delicate materials.

Industrial Applications and Roles of Conveyor Systems in Different Sectors

Conveyor systems play an important role in many industries. They are particularly common in the automotive, food, textile, electronics, and logistics sectors. These systems accelerate the flow of materials in industrial processes, increase production speed, and reduce the rate of defective products. For example, in the automotive sector, an assembly line ensures that vehicle parts are transported in the correct order and at the correct speed for each stage.

Let’s look at examples of how conveyor systems benefit these industries. In the automotive industry, conveyors ensure that parts are transported smoothly along the assembly line and that assembly is carried out quickly. In addition, in the food industry, conveyor systems allow products to be transported hygienically. Furthermore, in warehouses and logistics centers, conveyor systems enable products to be quickly and safely packaged and prepared for distribution.

The industrial applications of conveyor systems not only speed up production processes but also improve safety. For instance, workers no longer need to carry heavy loads, which reduces workplace accidents and protects employee health. Moreover, automated transportation processes minimize human errors and prevent material losses.

Advantages of Conveyor Systems: Solutions Providing Efficiency and Time Savings

One of the biggest advantages of conveyor systems is their ability to increase efficiency. These systems replace manual labor by automating transportation and material flow processes. This reduces labor costs and makes operational processes faster. So, what other factors increase efficiency? Here are some:

- Automated Transport: Conveyors automate the product transport process, providing speed and accuracy. This allows employees to focus more efficiently on other tasks.

- Time Savings: Conveyor systems shorten material handling times. This increases production speed and allows production capacity to rise.

- Reduced Error Rates: Automated transportation processes eliminate manual errors and ensure smooth operations.

- Labor Savings: Employees can be directed to more value-added tasks instead of carrying heavy loads.

In addition, conveyor systems reduce production costs by preventing material losses. Materials are less likely to be damaged during transportation and are transferred efficiently. This ultimately increases the company’s profit margin.

Types of Conveyor Systems: Differences Between Belt, Roller, and Tube Conveyors

Conveyor systems are divided into different types depending on the purpose of transportation and operating conditions. Belt, roller, and tube conveyors each have different designs and advantages, providing the most suitable solution for specific applications. Let’s take a closer look at the differences between these types:

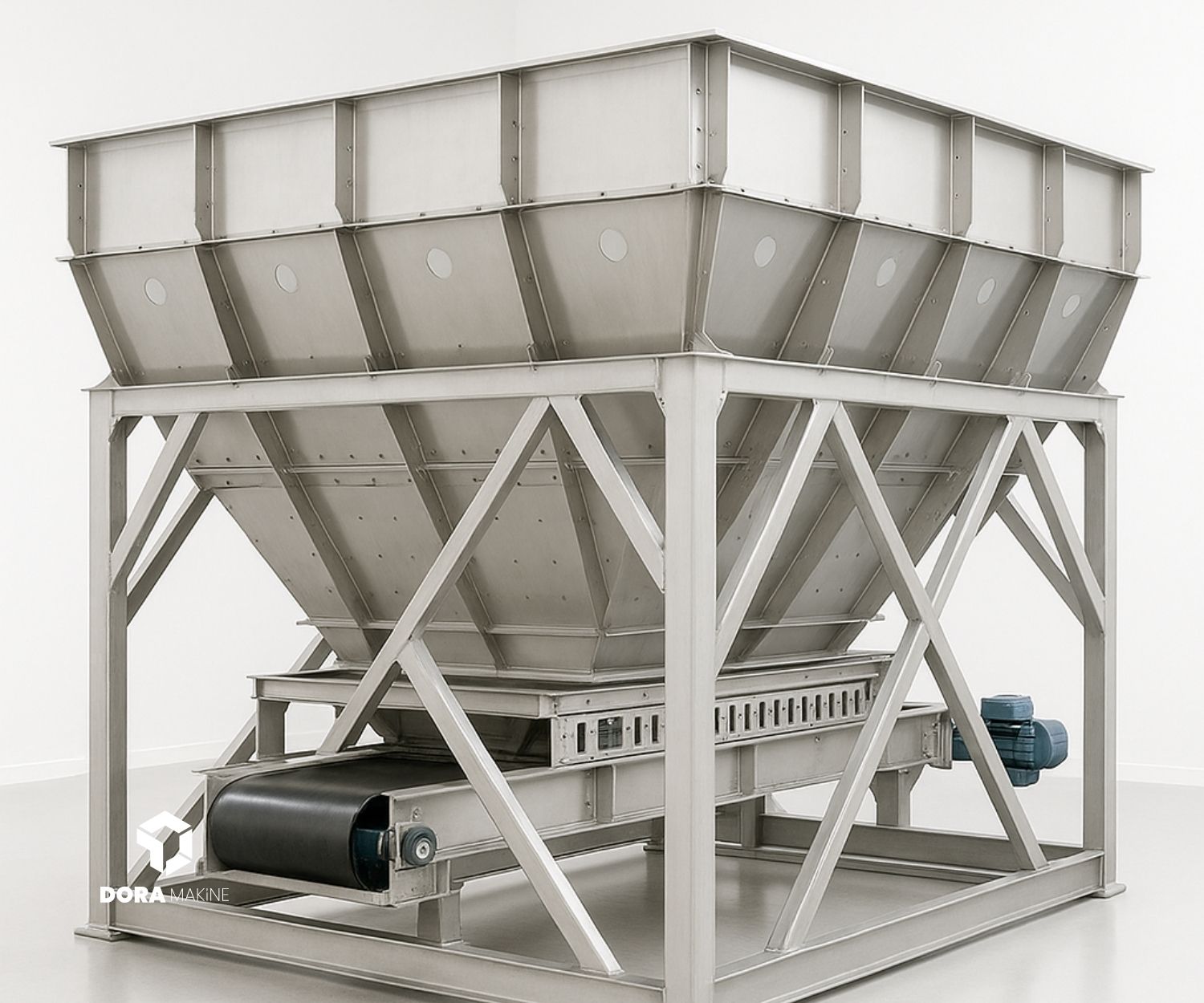

Belt Conveyors

Belt conveyors are one of the most common types of industrial transport systems. They are generally used on flat surfaces, where the material to be transported slides over the conveyor belt. Belt conveyors are particularly effective in the food industry and in light material handling. They can easily transport over long distances and can be adapted to a wide range of applications.

Roller Conveyors

Roller conveyors are generally used for transporting packaged materials. This system moves materials through cylindrical elements that rotate like rollers. Roller conveyors are ideal for carrying heavy loads and efficiently transferring packaged products. In addition, these conveyors can operate smoothly even in inclined areas.

Tube Conveyors

Tube conveyors are preferred especially for materials that need to be transported in powdered form or with special care. Their tube-shaped transport surfaces securely carry materials while protecting them from external factors. Tube conveyors are used in the chemical, pharmaceutical, and food industries. The advantage of these conveyors is that they can operate without being affected by environmental factors (such as weather conditions or dust).

In conclusion, the types of conveyor systems are shaped according to the specific needs of each industry. The choice between belt, roller, and tube conveyors depends on the type of material being transported, the transportation distance, and environmental conditions.